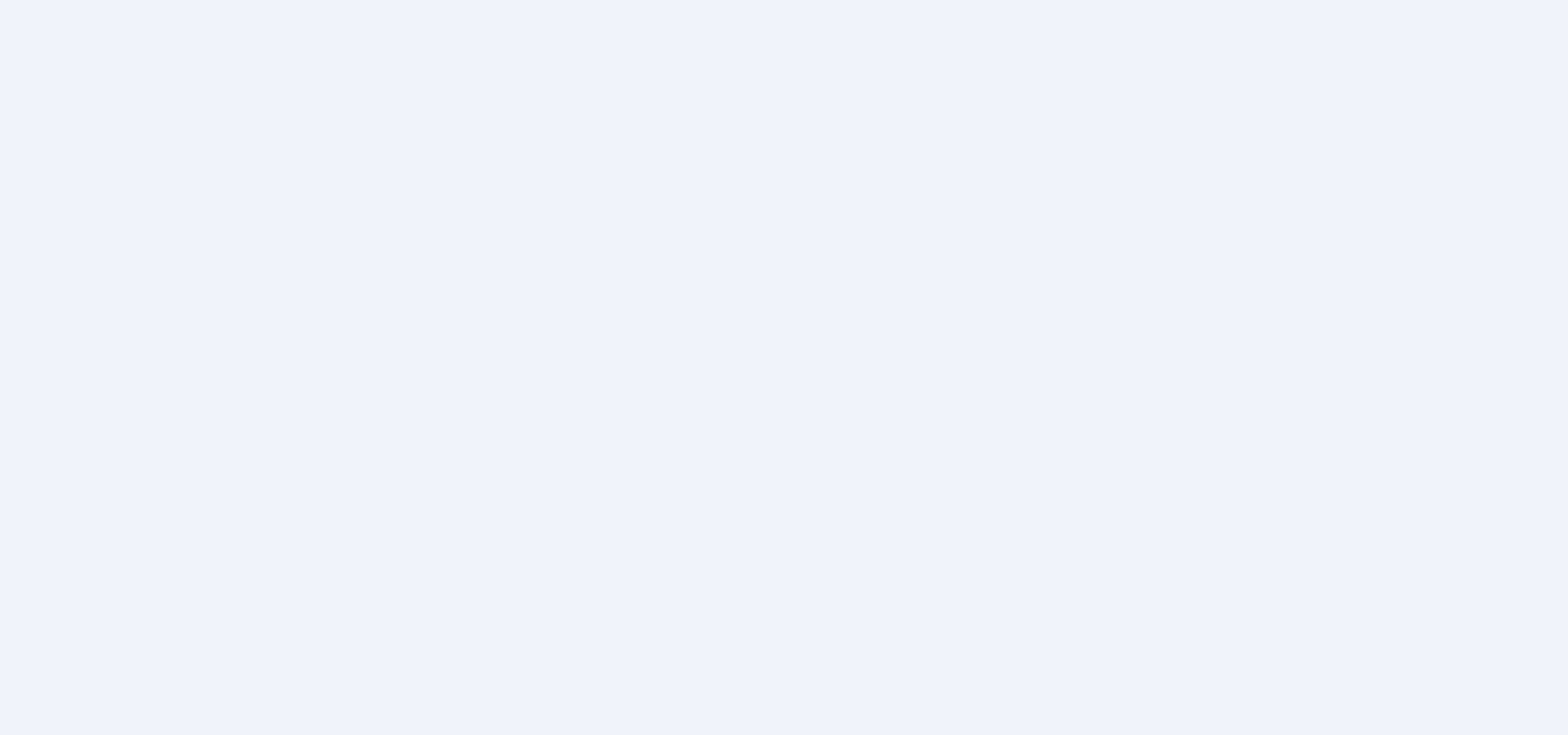

TASD Screw Chiller

Air-cooled modular design

Cooling capacity: 385 – 1425 kW

Screw compressor, R134a

- Modular design

♦ The unit adopts the modular design. Each microcomputer controller of the unit reserves the interface for connecting the combined control module. Networking control between units can be implemented by cable connection and simple master-slave settings. A maximum of 8 main units can be controlled in a combined manner, which means that the unit capacity can be easily expanded to meet various air-conditioning requirements in different places. ♦ The main unit can be used to manage all modules in a centralized manner, select the number of modules, and monitor the operating data and status. ♦ Modules are independent of each other. A single failure of a module in a unit does not affect the operation of the other modules. ♦ The unit is provided with standard RS485 interface and supports the MODBUS-RTU protocol. It can implement centralized control and remote monitoring of the unit, and regulate other chiller auxiliaries as required by the BAS.

- High efficiency compressor

♦ The highly efficient semi-hermetical twin-screw compressor adopts the world-class latest generation 5:6 patented asymmetric tooth-type rotor to greatly improve the adiabatic efficiency. This type of high-efficiency motor with large capacity can significantly enhance the energy efficiency. ♦ The compressor motor directly connects to the rotor with no gearbox involved, which avoids energy loss caused by gear transmission; moreover, fewer moving parts can ensure lower noise and a more reliable operation. ♦ The high-precision filter screen built in the compressor increases the oil separation efficiency up to 99.5%. ♦ The unit adopts the semi-enclosed twin-screw compressor and air suction cooling motor to ensure that the motor is fully cooled. ♦ The compressor adopts the slide valve for adjustment. A single compressor can precisely match 25% – 100% load changes, and dual-compressor up to 12.5% – 100% load changes, which reduces operating expenditure to the greatest extent.

- High efficiency heat exchanger

♦ The patented counter-current water-side heat exchanger, combined with the inner-threaded efficient heat exchange pipe, can increase heat exchange efficiency by 20% to 30%. ♦ The wind-side heat exchanger adopts a unique process design to ensure that the refrigerant is in the best flow rate in any condition. In this way, the refrigerant pressure in the wind-side heat exchange copper pipe can be reduced to a minimum, which effectively decreases the power consumption of the compressor and improves the energy efficiency of the unit. ♦ The use of inverted “M” type heat exchanger reduces ventilation resistance, improves air flow velocity distribution, and increases heat exchange efficiency. ♦ The use of large air volume silent fan increases the air flow through the tube fins, which improves the heat exchange efficiency of the wind-side heat exchanger. ♦ The graded control of the unit fan effectively reduces the fan power consumption of the unit in the transitional ambient temperature. ♦ The use of new open-window aluminium fin greatly enhances the gas turbulence of the wind-side heat exchange tube and the surface of the fin. In this way, the heat exchange efficiency is increased by about 8%.

- Unit microcomputer control center

The industrial-level microcomputer controller, together with the LCD touch screen, constitutes the control unit of the unit. While TICA’s unique self-control technology and up-to-edge control technology in the world create powerful control functions of our controller. The leading intelligent control program ensures accurate management of water temperature under any condition and guarantees energy-saving, safe, and stable operation of the unit by automatic control. Meanwhile, the advanced pre-control function enables measures to be taken timely before actual failure occurs to avoid frequent shutdown of the unit. The unit supports the compiling of weekly operating schedules to implement comprehensive automatic start and stop control of the unit, which truly implements unattended and automatic operation.

Submit the product inquiry form with your questions to get a PDF product brochure with technical specifications.

Need Some Help?

Whether you’re stuck or just want some tips on where to start, hit up our experts anytime.

Our contact details

enquiries@ticapacific.au & +61 410 067 300